Dat-A-Control Software

The iCUBE is managed and controlled using our proprietary Dat-A-Control Software

This software package uses two main applications: Dat-A-Control and Dat-A-WMS.

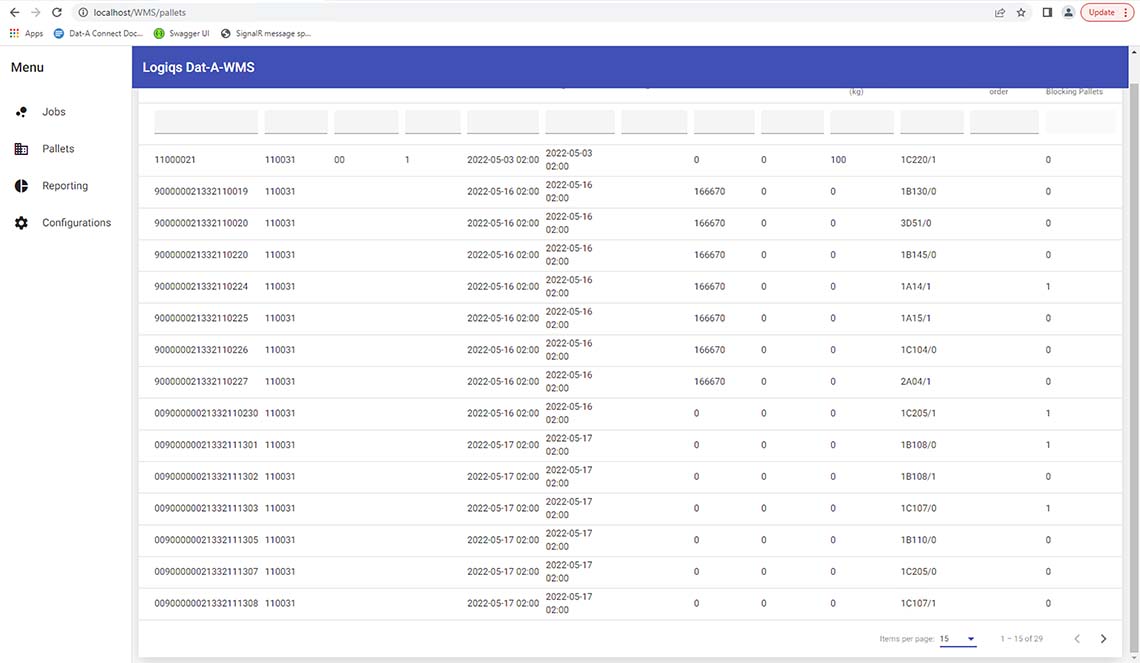

Dat-A-Control automatically handles the machine movements and controls, while Dat-A-WMS handles the space and inventory management in the warehouse.

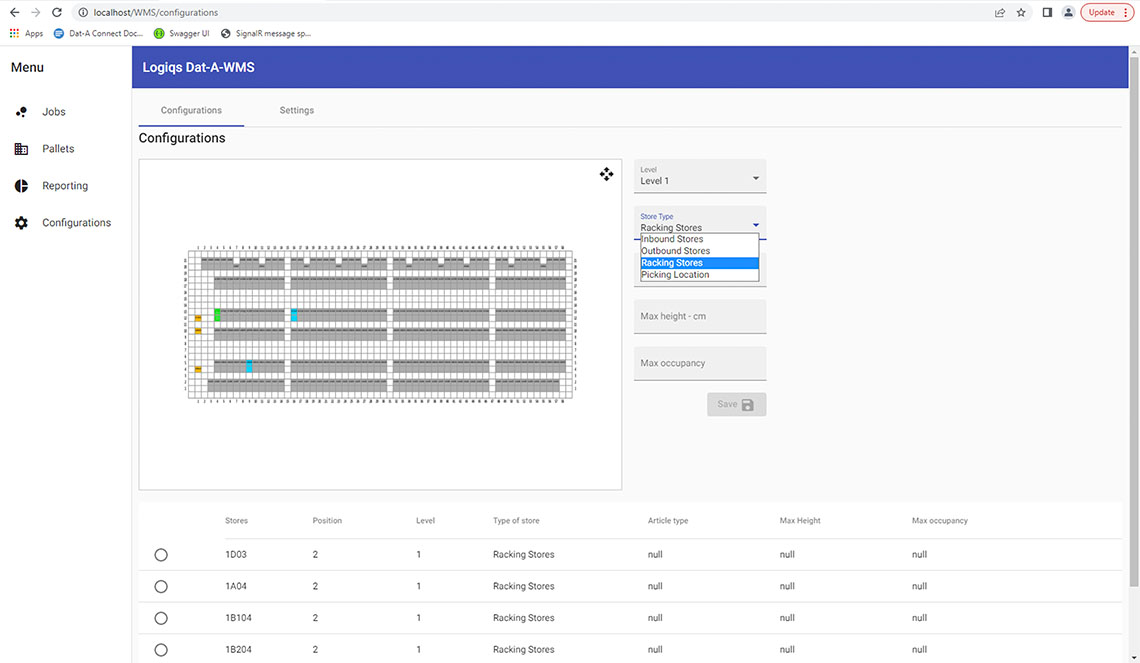

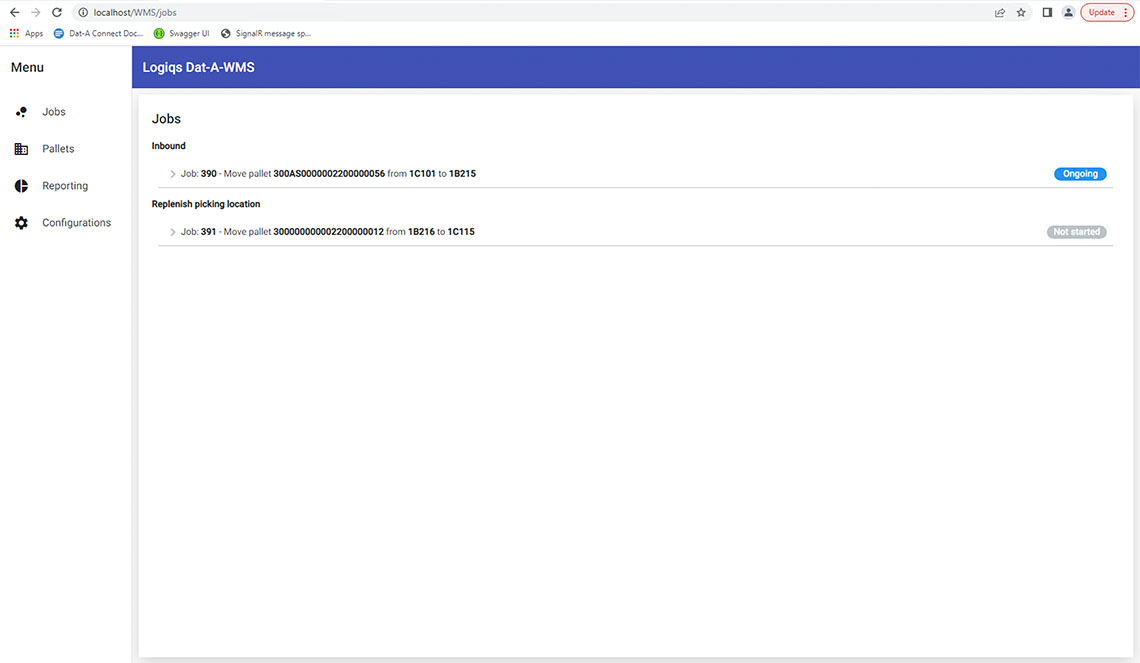

Dat-A-WMS allows the operators to configure the storage strategy for each individual location in the iCUBE as well as prioritize between inbound, outbound and order picking.

Because of the codeless configurability, operators can customize the allocation logic of the system according to their business requirements.

Once the Dat-A-WMS has determined the allocation and/or fulfillment needs, Dat-A-Control then executes the tasks using advanced logistics algorithms that maximize the usage of the 3D-Carriers and Vertical Transporters.

The Dat-A-Control Software suite gives full control and unmatched flexibility to the warehouse operators, allowing them to fully automate operations and achieve the process flow they need for their operation.

The Dat-A-Control software communicates with external software through modern API’s permitting fast implementations with other ERP and WMS systems.

Unique Selling Points

Useful links

Design your AS/RS

Get in touch with one of our Sales Engineers for more information

Phone: +31 174 514141

Email: info@logiqs.nl

Address: Honderdland 841, 2676 LV Maasdijk, The Netherlands