Hoog Bos Orchids

About Hoog Bos Orchids

A young and fast growing orchid nursery based in Nieuwaal, using a state of the art 3,5 hectares greenhouse that produces top quality Phalaenopsis. The nursery focuses on growing Phalaenopsis with at least three branches in 12 cm. pots. This allows them to concentrate on the high-end market segment in Europe and on customers who are looking for the best Phalaenopsis!

When the van Wijk family from Nieuwaal came to us a year ago with the challenge of fully automating their new 35.000m2 greenhouse. We were ecstatic to take on the challenge and committed to delivering the most flexible and cost effective internal transport logistics systems in the world.

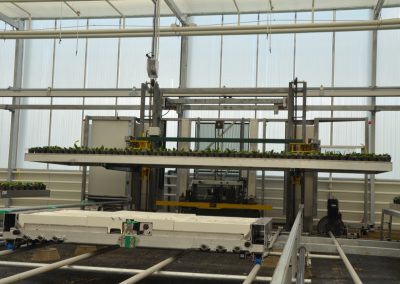

After carefully studying the specific requirements of the crop and the desired capacity of the greenhouse, we went on to design, produce and implement a fully automatic rolling bench system that uses more than 3000 rolling benches (5.810 mm x 1.630 mm) that allows for a yearly growing capacity exceeding 2.000.000 Phalaenopsis Orchids/year.

Location

Jordan Station,

Canada

Crop

Various potted plants and cut flowers

System

Rolling bench system with 2D-Shuttles

Surface

3 hectares

Some of the challenges that the logistics system had to be able to handle are:

- A desired potting capacity of 45.000 plants/week,

- A Shorter, more efficient growing cycle than the industry standard,

- A highly complex and specialised production process typical to orchids: the plants need to be re-spaced on the Rolling benches once during growth, at a later time support stick’s need to be applied to each individual plant, then organised in trays and at the end of the growing cycle the plants need to be efficiently sorted and packed for existing orders,

- A very flexible and efficient Order Picking system.

With five 2D-Shuttles, two AGW’s (Wall-Mounted Transport vehicles), two 3D-Cranes, and a completely automated working area, the rolling container system is now ready to handle volumes of plants that would be unmanageable in a conventional plant nursery.

By using the 2D-Shuttles, the client will have the benefit of fully automated by-directional pipelines in the entire growing area for a much lower price than by using individual automation for each pipeline with push or pull mechanisms, also leading to smaller long-term maintenance costs.

The 3D-Cranes also work towards a more flexible system, allowing for optimal order picking when plants are ready for selling as well as an optimal use of space.

After sales services

Logiqs has its own experienced installation and service team based in the Netherlands, but also collaborates with reliable service engineer teams in several countries so as to prevent unnecessary installation or maintenance costs.

Our customers can always rely on prompt and efficient attention for routine maintenance, breakdown or emergency situations.

Routine preventative maintenance can be tailored to the customer’s choice, with service intervals to suit the specific needs of the logistical system.

Design your Greenhouse

Get in touch with one of our Sales Engineers for more information

Phone: +31 174 514141

Email: info@logiqs.nl

Address: Honderdland 841, 2676 LV Maasdijk, The Netherlands