VDE Plant Upgrade

About VDE Plant

VDE plant is a real family business located in the beautiful countryside just outside the Dutch town of Woubrugge.

‘VDE’ stands for ‘Van Der Eijk’, the family name of the company’s founders.

Today, the third generation is running the business: brother and sister Karin and Edwin van der Eijk together with their partner, Hein Visser.

Ever since 1948, the team at VDE has been committed to growing the most beautiful tropical houseplants for consumers.

Location

Woubrugge,

the Netherlands

Crop

Potted plants

System

Automatic rolling bench system

Surface

90.000 m2

Summary

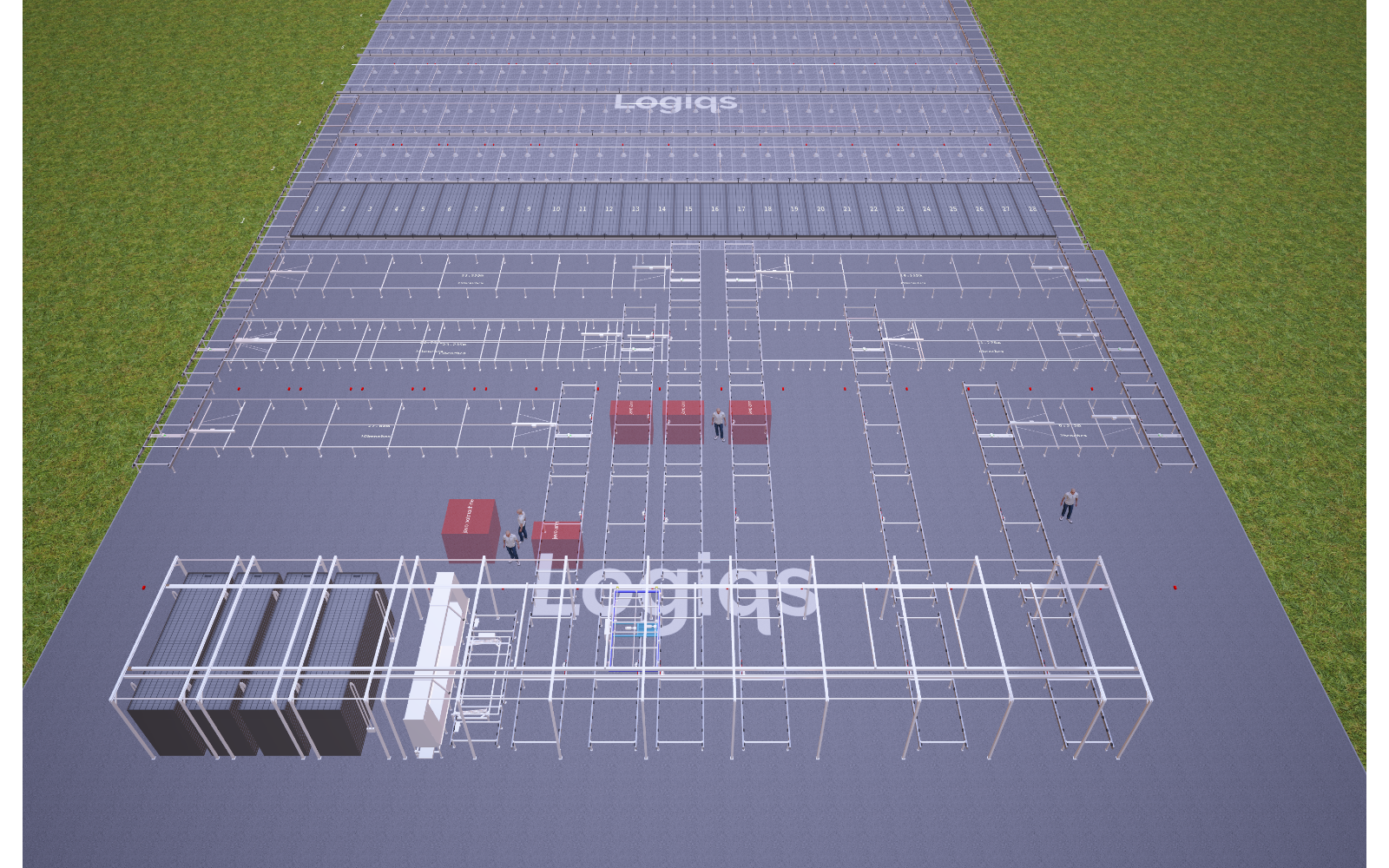

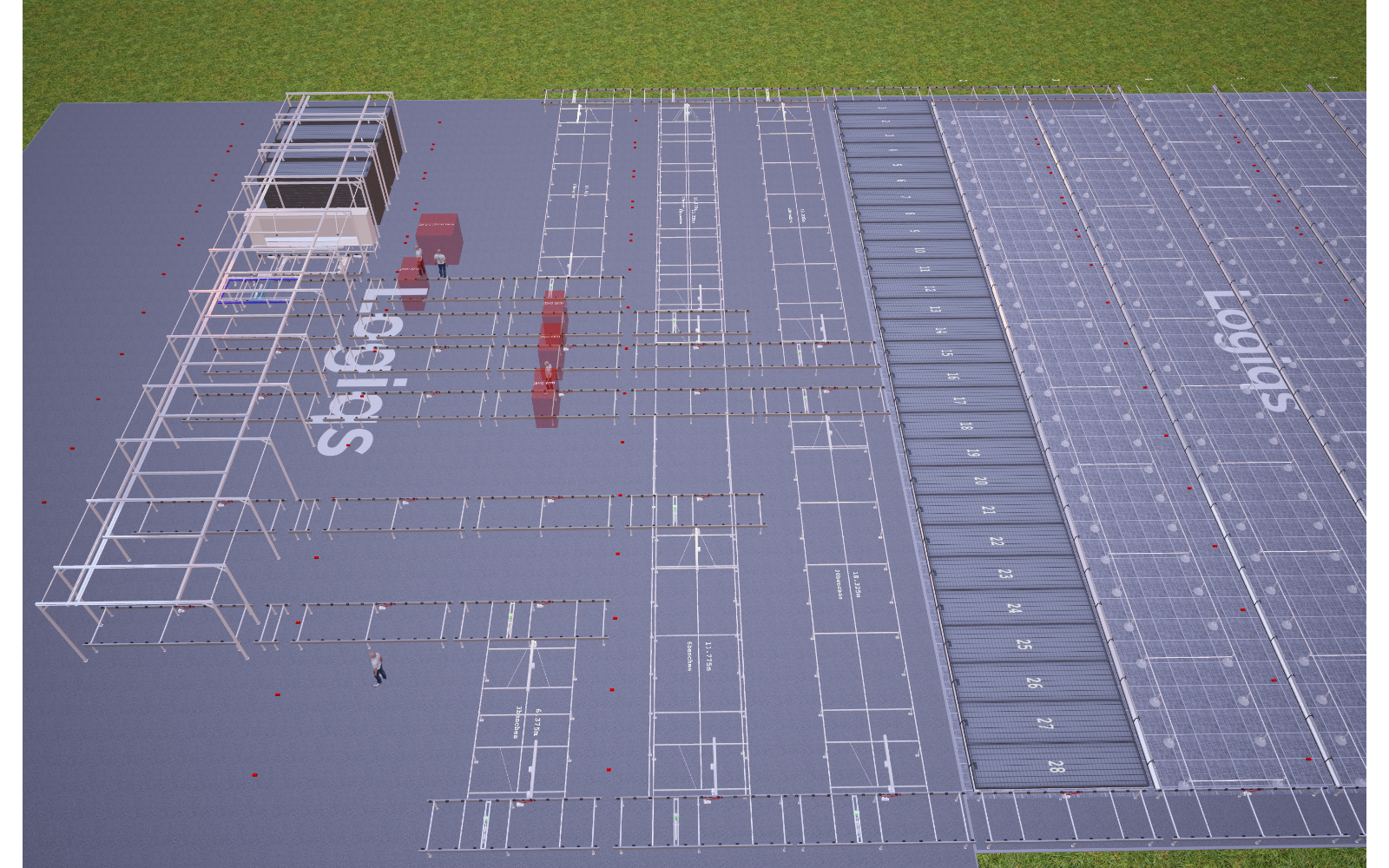

Logiqs recently modernized VDE-Plant’s 1986 processing room, a tropical plant nursery located in Woubrugge in The Netherlands, with upgrades to meet the current needs while making use of the technological advancements available today.

What made this project special, was how VDE Plant used the Logiqs’ online 3D-configurator for designing the mobile bench system for this project, resulting in a remarkable outcome.

Old system

New system

History

Soon after Logiqs was founded in 1975 (then known as Intransit), VDE-Plant in Woubrugge became one of the first customers for a mobile cultivation system. In 1986, a second nursery was built, with a modern automatic processing room for that time.

In the years that followed, VDE-Plant expanded to a 90,000 square meter growing area. This growth has been facilitated by an automated internal transport system and two processing rooms, which allow the nursery to cultivate more than 30 varieties of indoor green plants.

Logiqs kept the system running smoothly by being hands-on in its maintenance and adaptation during the years that followed.

Because of the strong bond that was formed during this time, the company’s dynamic trio of entrepreneurs – Karin van der Eijk, Edwin van der Eijk, and Hein Visser – approached Logiqs with the challenge of modernizing the processing room at A. de Graaflaan.

Project

Highlights of the automated benching system we delivered are:

- Three automated transport vehicles

- Three Overhead Crane for the management of empty benches

- One Overhead Crane for movements of full rolling benches

- One rolling bench Lift

- Two 100 Degree Bench Cleaners

- Several A-track automated transport lines.

Type of rolling benches: with aluminium ebb and flood.

Challenge

In the early days, the aim was to minimize the processing room’s footprint and maximize the plant cultivation area – because that’s the biggest revenue generator. But as time went by, the importance of an efficient work environment and enough space to handle large orders became increasingly apparent.

That’s where Logiqs stepped in, to bring the processing room at the VDE-Plant tropical plant nursery up to date, with the help of our innovative design system.

The challenge was to design a new, efficient processing room with enough storage capacity for handling big orders, while ensuring minimal disruptions in day-to-day operations.

Solution

With years of experience in designing efficient processing rooms, Logiqs already knows the importance of balancing the customer’s needs with the practicalities of the space.

The key challenge is to understand the diverse and often conflicting needs of the customer, brought in by various stakeholders.

To streamline this process and allow for more creativity on the grower’s end, Logiqs offers an innovative solution: a user-friendly online design system:

Sjors Volwater and Philippe Halma work tirelessly and dedicated to streamline operations in the processing rooms. With a proactive approach during the planning stage, they crafted solutions tailored to meet the specific needs and requirements of the people who will be using it. Leading to fewer mistakes and smoother transitions.

Result

With careful planning and precise execution, the design process came to life with stunning results. From the initial idea to detail engineering, production, installation and delivery, everything went smoothly, and in 7 months from starting the detailed engineering for the project, the result was a fully operational system that exceeded expectations.

Both VDE Plant and Logiqs are proud of their successful collaboration. Their strong bond and seamless teamwork allowed the project to run smoothly from start to finish, resulting in an efficient processing room, fulfilling the client’s needs.

Software

The entire rolling bench system is controlled using our industry leading control and registration software Dat-A-Control.

Besides the control of benches and machines, Dat-A-Control also gives the grower full access to the registration database for plant movements and undergone production processes, making the management of the nursery more efficient.

After sales services

Logiqs has its own experienced installation and service team based in the Netherlands, but also collaborates with reliable service engineer teams in several countries so as to prevent unnecessary installation or maintenance costs.

Our customers can always rely on prompt and efficient attention for routine maintenance, breakdown or emergency situations.

Routine preventative maintenance can be tailored to the customer’s choice, with service intervals to suit the specific needs of the logistical system.

Design your Greenhouse

Get in touch with one of our Sales Engineers for more information

Phone: +31 174 514141

Email: info@logiqs.nl

Address: Honderdland 841, 2676 LV Maasdijk, The Netherlands