Rolling benches

Throughout the last decades rolling bench systems have become the industry standard in large scale greenhouse plant nurseries

With more than 45 years of experience and know-how, gained in the field of internal transport and logistics systems for greenhouses, Logiqs is recognised world-wide as one of the industry leaders in automated rolling bench systems.

Our rolling bench/container systems have been implemented in countless greenhouse, for a large variety of crops, such as:

- Potted plants

- Herbs in pots;

- Bulb flowers

- Young plants

- Cut flowers

- Cresses and microgreens

- Chrysanthemums

- Mushrooms

Rolling bench greenhouses allow for better organised work areas (potting, spacing, harvesting, packing, etc.) and always lead to more efficient working conditions.

Greenhouse using rolling bench systems also benefit from a more consistent working climate because of the improved airflow within the greenhouse, especially underneath the benches, compared to crops grown at ground level.

Rolling bench systems offer a multitude of advantages when compared to fixed table systems and/or growing on the ground.

Some of these advantages are:

- Efficient handling of different groups of plants or SKU’s with different growing conditions, by working with individual containers that can be moved and tracked throughout the grow/production cycle

- Optimal space usage to help the grower reach and surpass his targeted output

- Gives the grower the possibility for multi-level (vertical farming) growing solutions for an unparalleled space usage efficiency

- More efficient plant irrigation with reduced labour costs

- Efficient heating of the crop compared to growing on the ground, and therefor lower heating costs

- Streamlines all production processes in a large scale plant nursery

Because of the much more efficient irrigation possibilities, the overall humidity in the greenhouse can be lowered, and this reduces the risks of mildew, fungi and root diseases that can affect the plants!

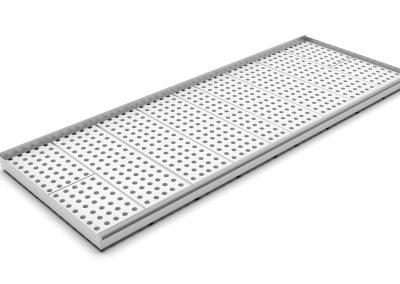

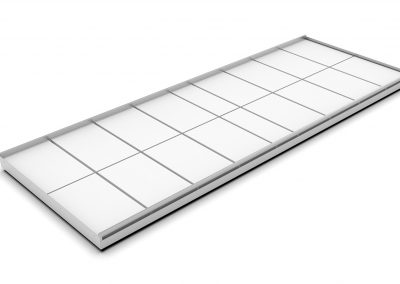

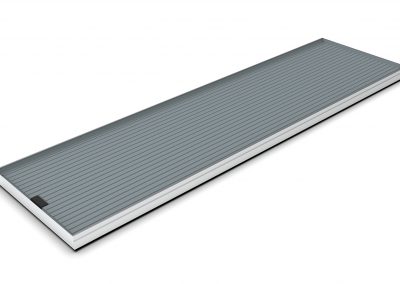

Rolling benches can be equipped with the following bottom types:

- Galvanised mesh inlay

- Expanded metal inlay

- Ebb and flood plastic inlays

- Styrofoam inlays

-

No inlay, suitable for tulip/bulb-flower crates

- Coated aluminium gutters

We work together with the customer on each project to determine the ideal rolling bench size according to the needs of the crop and the dimensions of the greenhouse (especially those of the aisles formed between resistance pillars).

Read more

Afterwords, the rolling benches are produced in our factory so that the welding is done in an ideal environment.

For projects where shipping large benches is difficult can also make use of the Moduline rolling benches which require no welding and that can be assembled on location.

Why a Logiqs rolling bench system?

Our long-term relationships with growers help us to fully understand their needs and ambitions and reach the desired automation results at the best possible price point.

We believe in sustainable automation and we don’t automate just for the sake of doing so. Because we only succeed when our customers are also successful in their production activities.

When necessary, long term phased plans can be made where the grower can fully understand how the greenhouse’s logistical system can be upgraded in time, even going from manual systems to a full automation level.

Design your Greenhouse

Get in touch with one of our Sales Engineers for more information

Phone: +31 174 514141

Email: info@logiqs.nl

Address: Honderdland 841, 2676 LV Maasdijk, The Netherlands