OK Plant

About OK Plant

OK Plant is an innovative grower recognised worldwide as a trendsetter with its product range and added value concepts.

Because of their passion for plants, OK Plant is constantly looking to develop new and sustainable products that meet and surpass the expectations of its customers.

OK Plant grows both seasonal and year-round products. Their year-round product is Little Kolibri Orchids. Some of the seasonal plants grown by OK Plant are: Campanula Addenda®, Aster Star Letta, cyclamen and Primula Obconica Touch Me.

Location

Naaldwijk,

The Netherlands

Crop

Campanula Addenda®, Aster Star Letta,

cyclamen en Primula Obconica Touch Me.

System

Rolling bench system with 2D-Shuttles

Surface

2,5 hectares +

3,5 hectares existing greenhouse

The project

In July of 2016, OK Plant began building a new 25.000 m2 greenhouse to match the ever-growing demand for their products.

The new greenhouse was built in Naaldwijk, the Netherlands, right next to the existing facility, with which it has been fully integrated.

The new greenhouse is used as an extra cultivation area but features a state of the art work area for potting, spacing, and staking.

The grow area

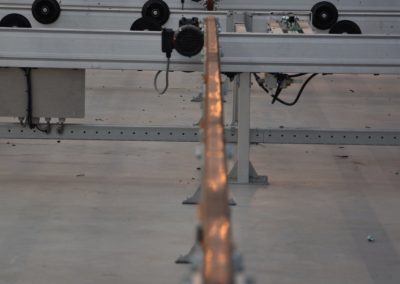

The new cultivation area is fully automated using our innovative 2D-Shuttles working together with automatic transport lines for efficient internal transport of the benches.

This new cultivation area will house more than 1.700 mobile benches (with steel mesh bottoms) each measuring 6,1 m * 1,7 m, and is fully automated using just two of our innovative 2D-Shuttles. To have achieved the same level of automation using conventional push-pull systems would have required installing approximately 40 fixed push-pull systems all adding up to a much higher automation cost. The high capacity automatic transport lines connect the growing area to the working area and to the existing greenhouse.

The work area

The new working area makes use of the existing overhead crane and multiple bench buffers/stacks for empty bench management and uses automatic transport lines to integrate the potting and spacing machines into the logistical system.

Existing Greenhouse

The existing facility also benefited from this extension and has undergone a full redesign of its logistical flow. That means that this greenhouse was also fitted with a 2D-Shuttle system and the manual transport lines wore fitted with ADU motors to automate them. This was the second time we got the opportunity to also implement our 2D-Shuttle system in an existing greenhouse.

Software

The entire rolling bench system is controlled using our own control and registration software: Dat-A-Control. The software package also features all necessary modules for such an ambitious project, integrating potting, spacing, and internal transport into one coherent system.

After sales services

Logiqs has its own experienced installation and service team based in the Netherlands, but also collaborates with reliable service engineer teams in several countries so as to prevent unnecessary installation or maintenance costs.

Our customers can always rely on prompt and efficient attention for routine maintenance, breakdown or emergency situations.

Routine preventative maintenance can be tailored to the customer’s choice, with service intervals to suit the specific needs of the logistical system.

Design your Greenhouse

Get in touch with one of our Sales Engineers for more information

Phone: +31 174 514141

Email: info@logiqs.nl

Address: Honderdland 841, 2676 LV Maasdijk, The Netherlands